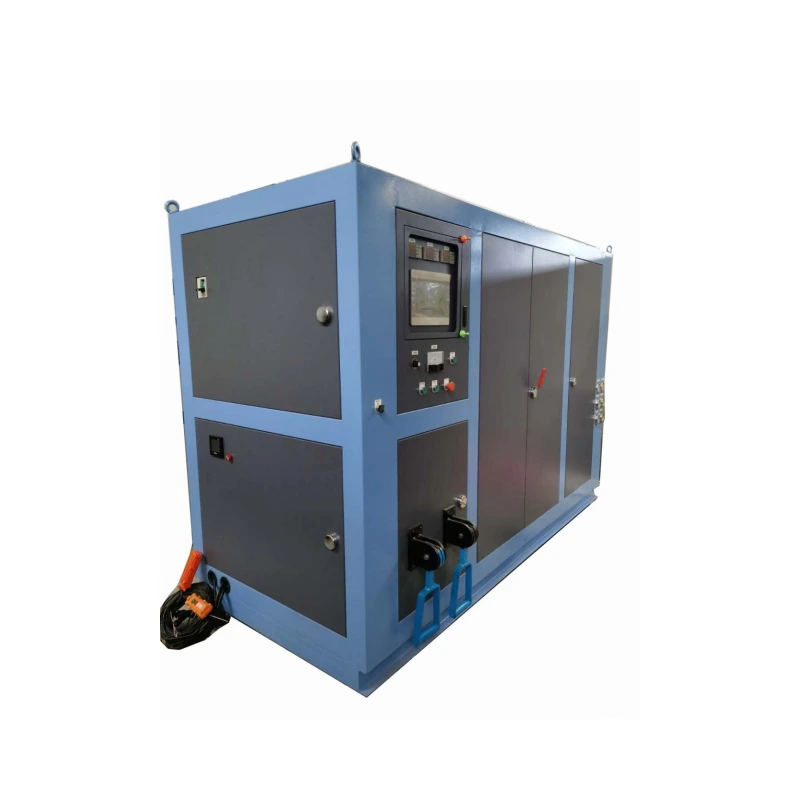

Jar Hing medium frequency melting furnace 150kg with servo control KGYSC-250/3-SF-2

The Jar Hing medium frequency melting furnace 150kg with servo control KGYSC-250/3-SF-2 offers precise and efficient metal melting capabilities, making it ideal for industrial applications requiring high quality and consistent results. With its advanced servo control technology, this furnace ensures accurate temperature control and energy efficiency, resulting in cost savings and improved productivity for businesses.

| Model No. | KGYSC-250/3-SF-2 |

| Place Of Origin | China |

| Old And New | New |

| Video Factory Inspection | Provided |

| Mechanical Test Report | Not Available |

| Marketing Type | Ordinary Product |

| Core Component Warranty Period | 1 Year |

| Core Components | Plc, Motor, Pump |

| Warranty Period | 1 Year |

| Core Selling Point | High Productivity |

| Out-of-warranty Service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

None |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

| Applicable Industry | Other |

1. rated power: 250KW;

2. power factor 0.95;

3. melting rate ≤ 28min/ furnace;

4. the maximum temperature of molten steel is 1750 ℃;

5. the rated capacity of furnace body is 150kg*2;

6. furnace output voltage 1800V;

7. the new generation control board is adopted to improve the protection performance of the equipment and reduce the equipment failure rate; At the same time, there is no need for resistance wire and starting thyristor, which reduces the failure rate of the equipment again;

8. servo hydraulic furnace structure;

9. adopt series inverter mode; The power consumption of 1 ton of molten steel is about 600 degrees, which is about 240 degrees less than that of ordinary medium frequency furnace; Imported Fuji switch, Grundfos water pump, British Sima inverter diode.

10. the power cabinet has plc+ touch screen; Servo hydraulic furnace body is controlled by independent touch screen +plc.

1. rated power: 250KW;

2. power factor 0.95;

3. melting rate ≤ 28min/ furnace;

4. the maximum temperature of molten steel is 1750 ℃;

5. the rated capacity of furnace body is 150kg*2;

6. furnace output voltage 1800V;

7. the new generation control board is adopted to improve the protection performance of the equipment and reduce the equipment failure rate; At the same time, there is no need for resistance wire and starting thyristor, which reduces the failure rate of the equipment again;

8. servo hydraulic furnace structure;

9. adopt series inverter mode; The power consumption of 1 ton of molten steel is about 600 degrees, which is about 240 degrees less than that of ordinary medium frequency furnace; Imported Fuji switch, Grundfos water pump, British Sima inverter diode.

10. the power cabinet has plc+ touch screen; Servo hydraulic furnace body is controlled by independent touch screen +plc.

Room 805, Huaxu Building, NO.95 Renmin South Road, Taicang City, Jiangsu Province, Suzhou, Jiangsu, China