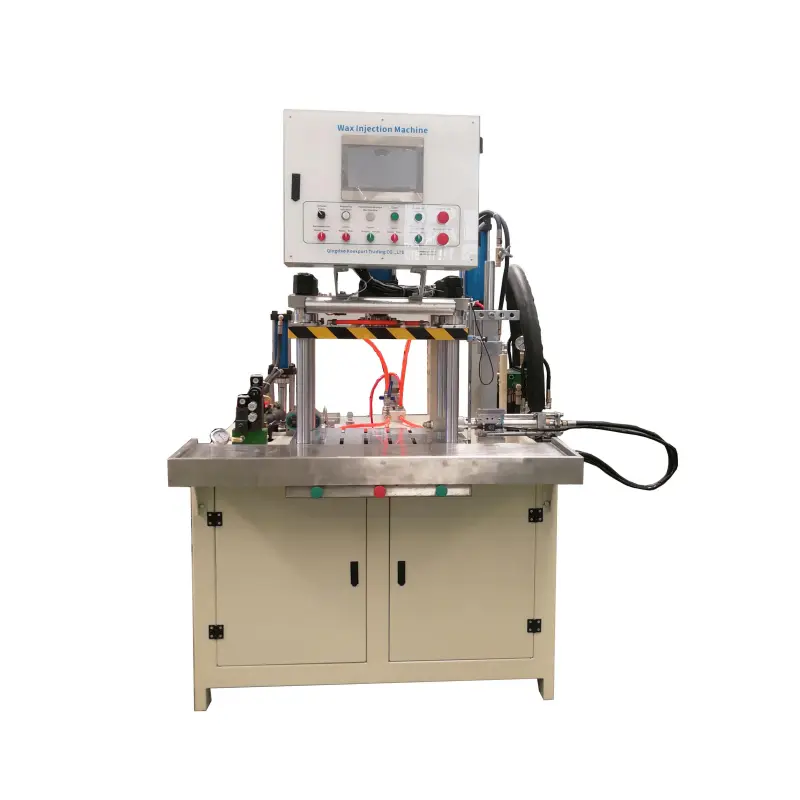

Jewelry Molding Machine by Jar Hing

Product details of the jewelry molding machine

Quick Overview

jewelry molding machine is manufactured based on advanced production technology. It is safe and highly-adaptable with stable performance and reliable quality. It is high in productivity and long in service life. All these make it highly competitive in the market. jewelry molding machine's design idea is based on the search for a high-quality life standard. The quality of this product is more assured by stressing the value of quality management. Excellent in performance and good in quality, jewelry molding machine is used for fermentation of all kinds of bread. Jar Hing Products Co., Ltd's years of development and exploration have developed various jewelry molding machine of different types.

Product Introduction

Compared with products in the industry, Jar Hing Products's jewelry molding machine has the outstanding advantages which are mainly reflected in the following aspects.

|

Model No. |

MYY10-1ZM |

|

Place Of Origin |

China |

|

Old And New |

New |

|

Video Factory Inspection |

Provided |

|

Mechanical Test Report |

Not Available |

|

Marketing Type |

Ordinary Product |

|

Core Component Warranty Period |

1 Year |

|

Core Components |

Plc, Motor, Pump |

|

Warranty Period |

1 Year |

|

Core Selling Point |

High Productivity |

|

Out-of-warranty Service |

Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

None |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Applicable Industry |

Other |

1. the maximum clamping force is 10t;

2. overall dimension 1865*1670*2100mm;

3. the minimum clamping height is 70mm;

4. equipment weight 1225kg;

5. die space 500 × four hundred and sixty × 385mm;

6. auxiliary workbench 1265 × 375mm;

7. expansion range of nozzle: 0 ~ 200mm;

8. the lifting range of nozzle is 0 ~ 200mm;

9. equipment power: 9.2kw;

10. single maximum wax injection quantity 3L;

11. wax injection pressure: 0 ~ 5MPa;

12. all oil cylinders, wax injection cylinders and wax replenishment cylinders shall adopt Japanese NOK sealing rings;

13. French Schneider shall be adopted for contactors and relays;

14. the touch screen is made of Taiwan vinylon;

15. temperature control mode touch screen +plc temperature control module;

16. the temperature control of wax injection and preparation adopts the independent heating and cooling type of insulation barrel, which avoids the valve sticking of previous equipment.

17. the hydraulic oil tank is made of stainless steel; The hydraulic oil is directly cooled by thick wall copper pipe, which avoids the potential safety hazard of hydraulic oil cooler freezing and water inflow in the past;

18. four column positioning pressure template, controlled by PLC touch screen, Automatic adjustment of nozzle can be used as two sets of molds, and it has the functions of high and low pressure and secondary high pressure wax injection; It has automatic core pulling function and automatic top mold function to meet the requirements of automatic mold production; Workbench auxiliary water cooling.

Company Information

Jar Hing Products Co., Ltd is an international jewelry molding machine company with extensive experience. It turns out that applying the best technology to the jewelry molding machine is a good idea. We are not focused on competing with other companies. We determine the market standard. This fact holds true when it comes to the characteristics and qualities of our individual products.

Jar Hing Products's Wax Injection Machine,Shell Moulding Machine,De-waxing and Wax Treatment Machine,Melting and Calcining Equipment,Post-processing Equipment,Low-temperature Wax Equipment,Auxiliary Equipment have multiple types and reliable quality. Customers from all walks of life are welcome to call us for consultation!

Room 805, Huaxu Building, NO.95 Renmin South Road, Taicang City, Jiangsu Province, Suzhou, Jiangsu, China