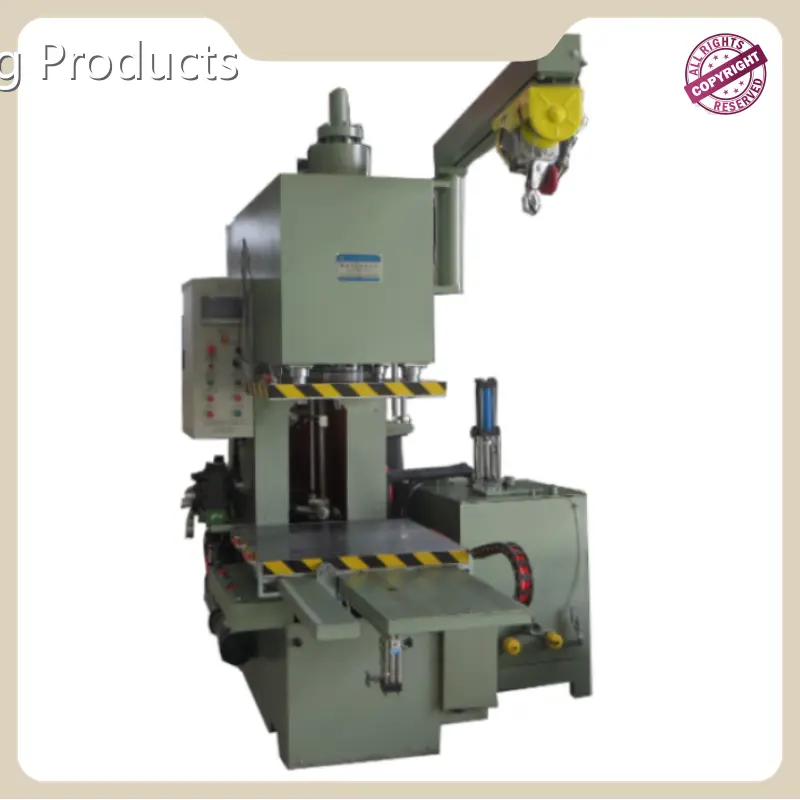

Wax Injector Wholesale - Jar Hing

Company Advantages

· The entire production process of Jar Hing wax injector strictly follows the international norms.

· The quality check team is totally responsible for the quality of this product.

· Our wax injector are of high quality with competitive price.

| Model No. | MMY20-1k |

| Place Of Origin | China |

| Old And New | New |

| Video Factory Inspection | Provided |

| Mechanical Test Report | Not Available |

| Marketing Type | Ordinary Product |

| Core Component Warranty Period | 1 Year |

| Core Components | Plc, Motor, Pump |

| Warranty Period | 1 Year |

| Core Selling Point | High Productivity |

| Out-of-warranty Service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Where To Provide Local Services | None |

| Showroom Location | None |

| Applicable Industry | Other |

| Item | Unit | MYY20-1KM | MYY50-1KM |

| Maximum clamping force | T | 20 | 50 |

| Maximum opening height | mm | 550 | 550 |

| Minimum mode height | mm | 100 | 100 |

| Upper plate size | mm | 600(L)×600(W) | 600(W)×600(W) |

| Lower worktable moving stroke | mm | 700 | 700 |

| Telescopic range of ejection nozzle | mm | 0~300 | 0~300 |

| Lifting range of ejection nozzle | mm | 0~300 | 0~300 |

| Ground height of work table | mm | 895 | 895 |

| Rated hanging weight of cantilever crane | Kg | 500 | 500 |

| Maximum use volume of wax storage cylinder | L | 120 | 120 |

| Single maximum paraffin amount | L | 7 | 12 |

| Wax injection pressure | MPa | 1.0~10 | 1.0~10 |

| Pressure holding time | S | 0~9999 | 0~9999 |

| Wax injection time | S | 0~9999 | 0~9999 |

| Installed power | KW | 10 | 10 |

| Temperature control mode | Touch screen +PLC temperature control module | Touch screen +PLC temperature control module | |

| Temperature control of wax storage bucket | ℃ | 75~90 | 75~90 |

| Isothermal temperature control | ℃ | 50~65 | 50~65 |

| Equipment dimensions | mm | 2520*1760*3000 | 2520*1760*3000 |

| Self weight of equipment | T | 3.0 | 3.9 |

1. Wax injection pressure: 0.5 ~ 10MPa;2. All oil cylinders, wax injection cylinders and wax replenishment cylinders shall adopt Japanese NOK sealing rings;3. French Schneider shall be adopted for contactors and relays;4. The touch screen is made of Taiwan vinylon;5. Temperature control mode touch screen +plc temperature control module;6. Fast running oil cylinder shall be adopted for die cylinder;7. Equipped with 0.5T mold lifting device;8. The temperature control of wax injection and preparation adopts the independent heating and cooling type of insulation barrel, which avoids the valve sticking of previous equipment.9. The hydraulic oil tank is made of stainless steel; The hydraulic oil is directly cooled by thick wall copper pipe, which avoids the potential safety hazard of hydraulic oil cooler freezing and water inflow in the past; At the same time, it has the function of hydraulic oil overtemperature alarm;10. High and low pressure wax injection, sliding plate can be removed; It has the function of one machine and two functions, which can shoot the die head quickly and large wax parts;11. It has the functions of high and low pressure and secondary high pressure wax injection; It has Automatic core pulling function and automatic top mold function to meet the requirements of automatic mold production.12. All processed parts of the pressing plate, worktable and nozzle advance and retreat lifting parts of the wax injection machine shall be chrome plated.

Company Features

· Jar Hing Products Co., Ltd is dedicated to the research, development, production, and sales of high-tech wax injector projects.

· Sticking to high standards, Jar Hing keeps improving the quality of products.

· Every stage of our operations presents an opportunity to eliminate waste. We have been focused on finding ways to reduce, reuse or recycle to divert waste from landfills. Contact!

Enterprise Advantages

Our company has a solid team of professional skills with modern awareness and superb skills to provide customers with strong technical support.

Jar Hing Products runs a comprehensive pre-sales and after-sales service system. We can effectively protect consumers' rights and interests and provide quality products and services.

Our company will, as always, fulfill our corporate mission of 'pursuing excellent quality and satisfying customer's needs', keep making progress and innovation, and provide customers with high quality and good service.

It has already been years since Jar Hing Products was established. During these years, we have realized the leap-forward development.

Jar Hing Products's Wax Injection Machine,Shell Moulding Machine,De-waxing and Wax Treatment Machine,Melting and Calcining Equipment,Post-processing Equipment,Low-temperature Wax Equipment,Auxiliary Equipment are sold to the whole country and exported to the Middle East, Europe, America, Africa, and other countries and regions.

Room 805, Huaxu Building, NO.95 Renmin South Road, Taicang City, Jiangsu Province, Suzhou, Jiangsu, China